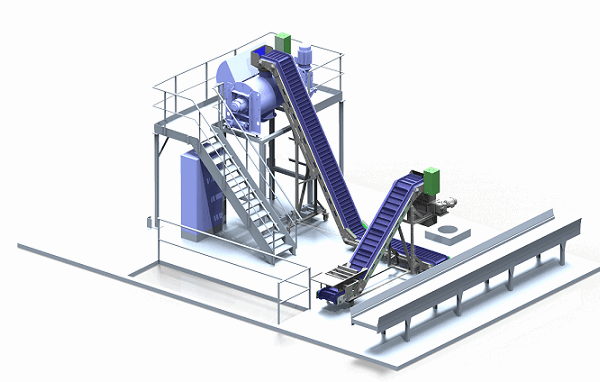

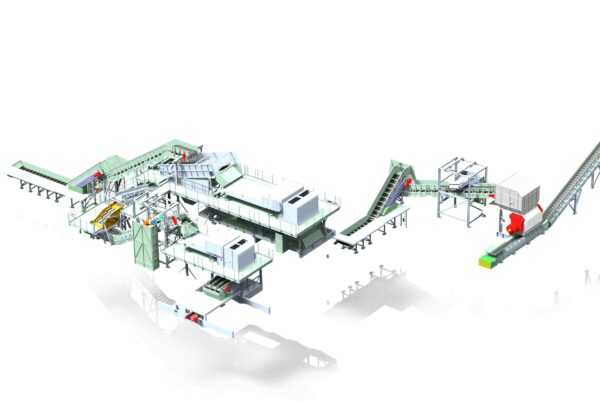

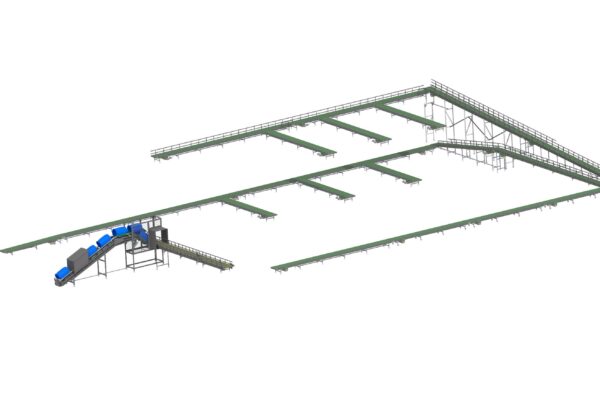

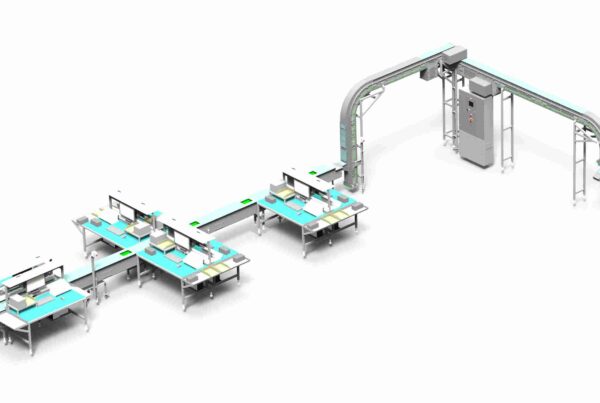

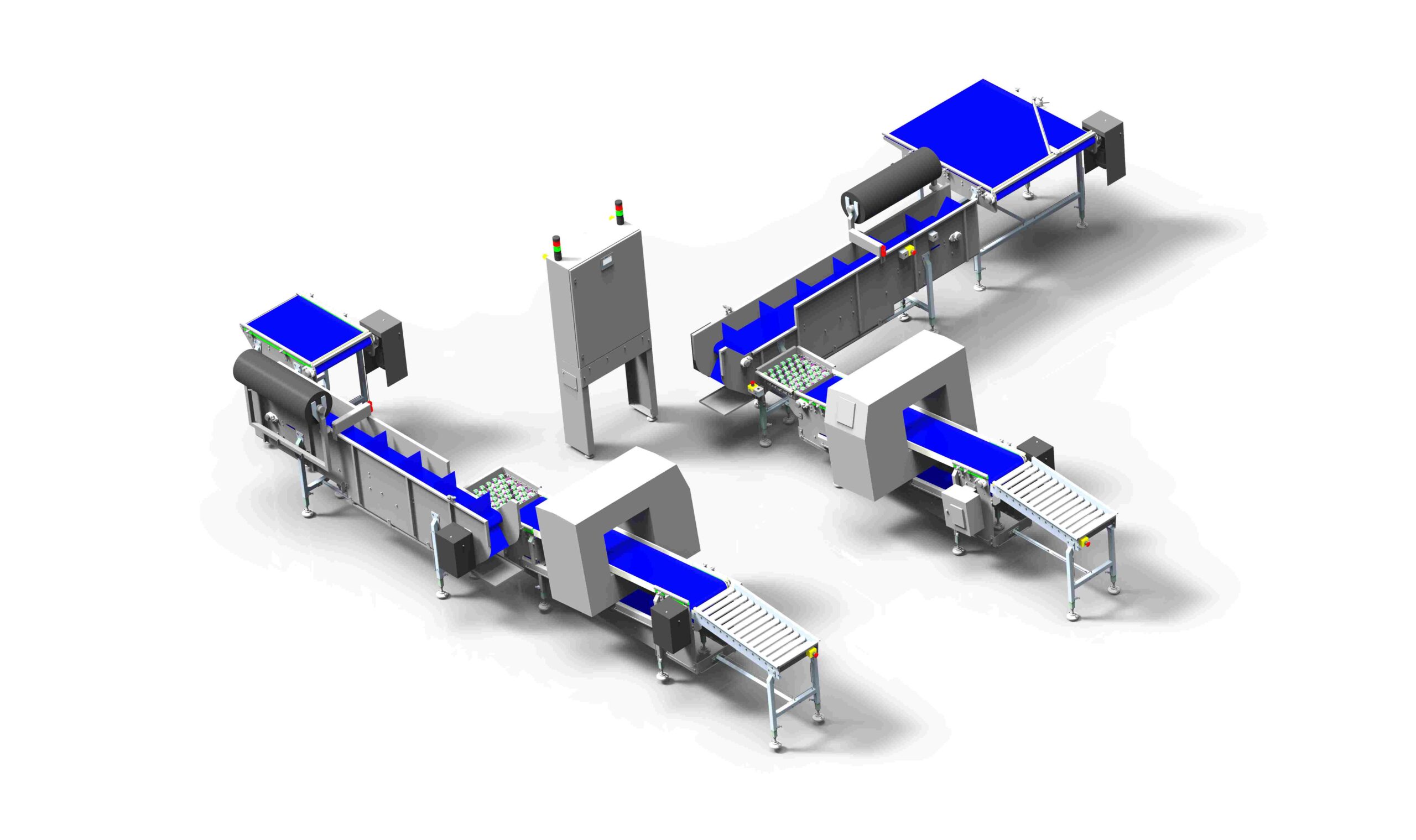

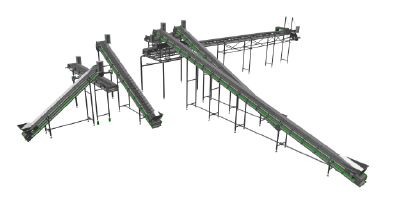

A complete process line refer to all the production lines at an industrial site carrying a company’s finished products. A complete process line generally consists of various industrial conveyors depending on the company’s handling needs, together with end-of-line systems for packaging the finished products. All complete process lines are different, and depend on the specific needs of an industrial company in terms of its activity sector. Benne SA offers its expertise in industrial handling to design complete process lines and conveyor systems tailored to the needs of your industrial site.

Benne SA, designer of complete process lines for industrial handling

As a designer and manufacturer of custom conveyors for the industrial handling sector, Benne SA can find conveyor solutions tailored to your industrial problems. Our complete process lines include all the conveyor lines that have ever been designed by our engineering office. Like all our conveyors, they are manufactured at our workshop in Castres by our qualified, experienced technicians. This continuity in the design and production of our complete process lines enables us to guarantee the total reliability of all our conveyor lines.

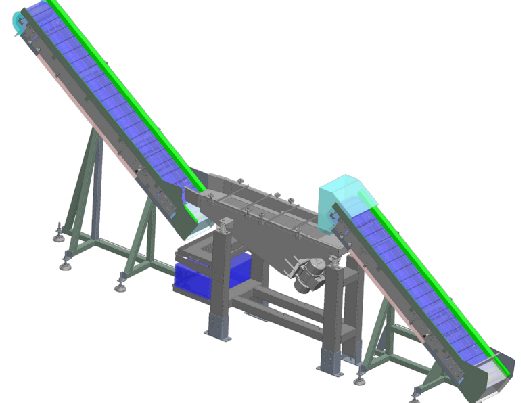

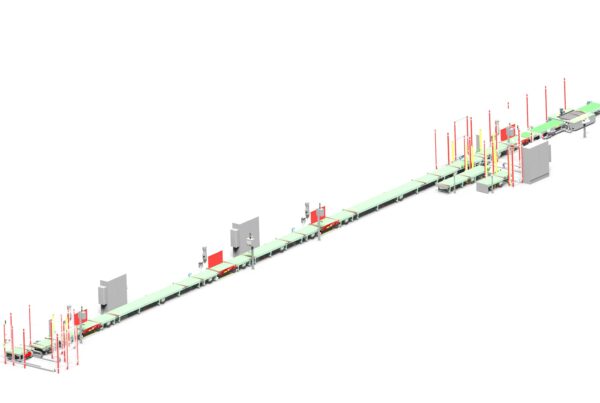

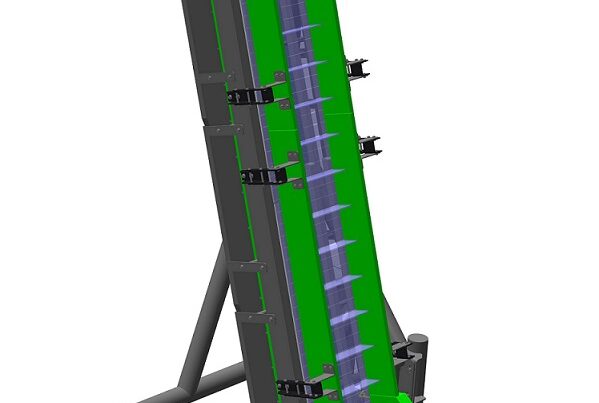

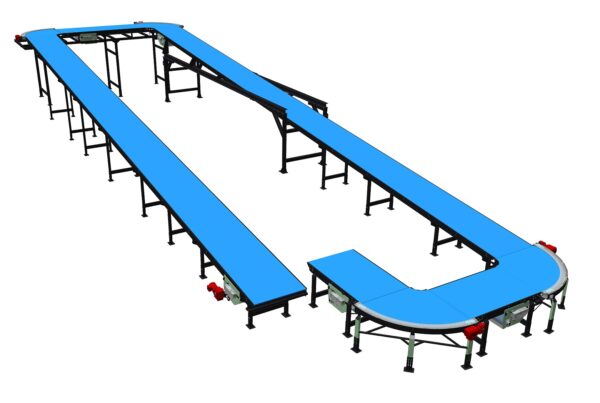

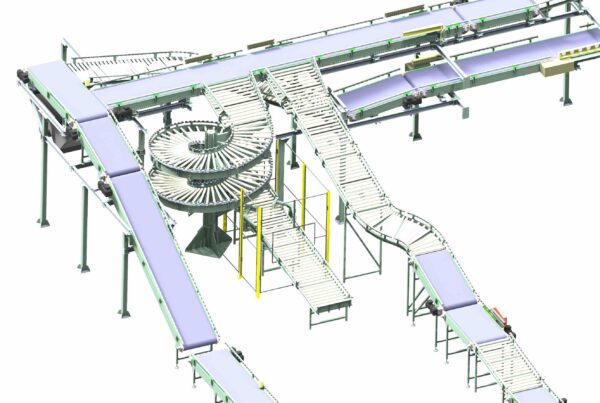

Our complete process lines are not just an assembly of standard industrial conveyors forming a complete production line. They always involve industrial conveyors custom-developed to suit the needs of your activity sector. Our compete process lines can also incorporate specific features depending on your industrial problems. These specific features include the integration of robotics, special machines and the creation of new industrial handling solutions. All these adaptations of our conveyor systems enable us to create complete process lines for any industrial company, regardless of activity sector.

Discover our many complete process line projects

Our expertise and our ability to adapt our conveyor systems to your specific needs enable us to design complete process lines for any activity sector. We work closely with sectors such as agri-food and pharmaceuticals, but also packaging, cardboard, textiles, automotive, timber, machinery and the chemicals industry.

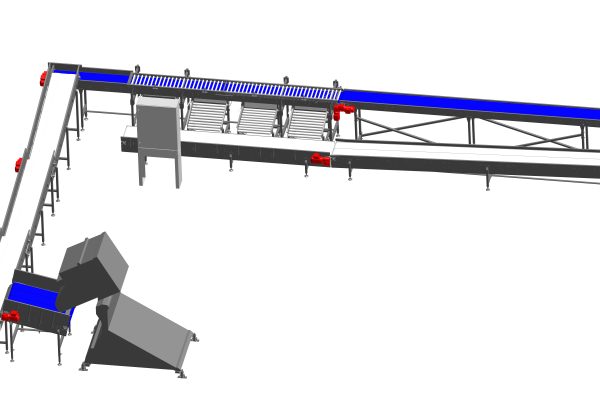

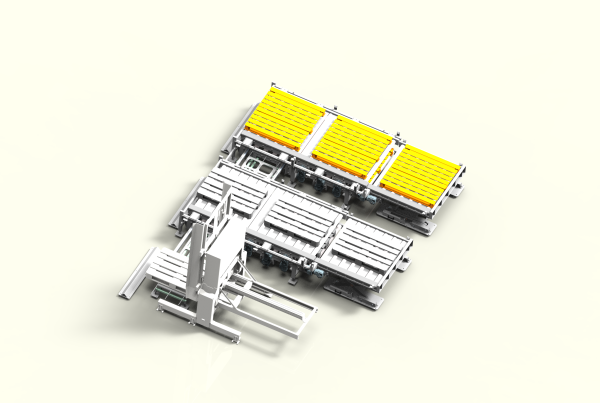

Thanks to Benne SA, you can find a turnkey conveyor solution to suit your needs in order to create a complete process line that meets your expectations perfectly. Create your custom complete process line based on our industrial conveyors:

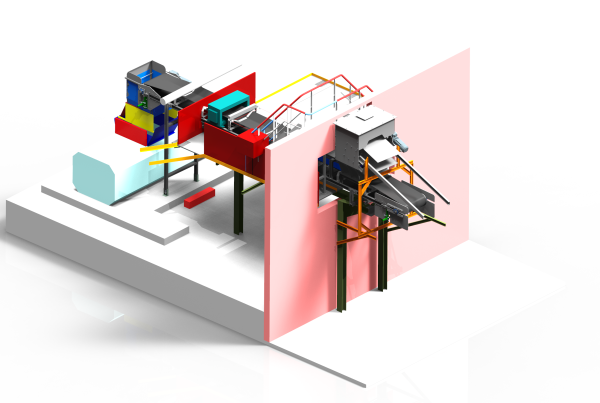

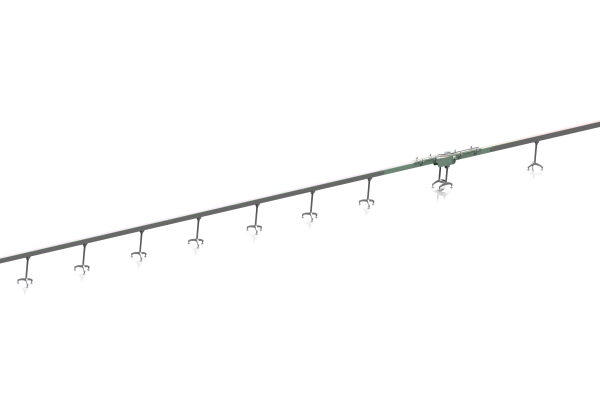

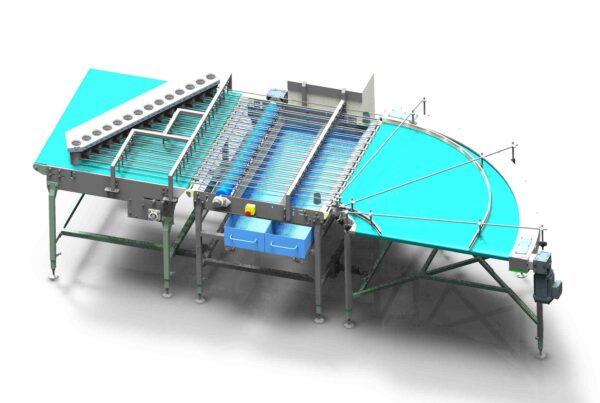

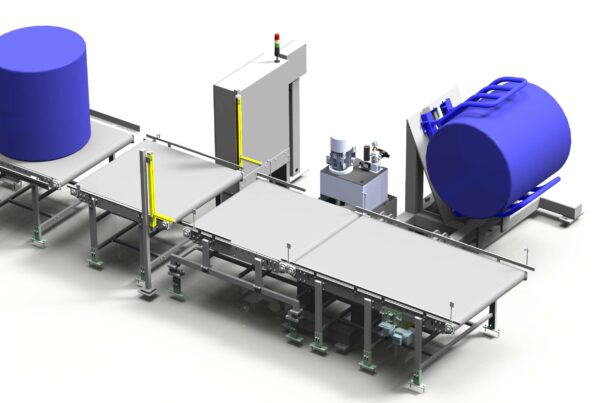

- Complete conveyor line for carrying plastic trays

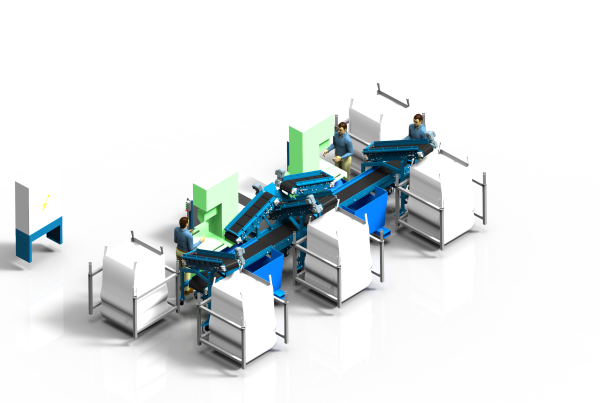

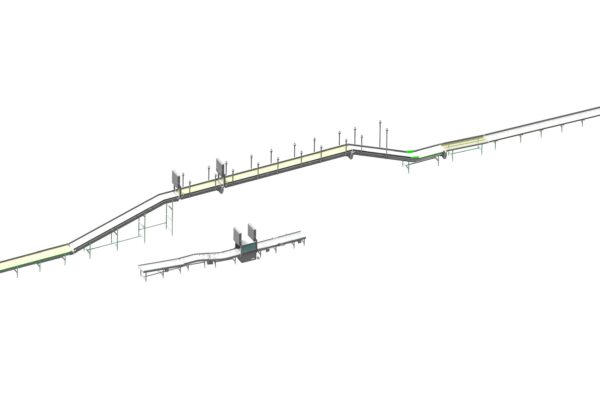

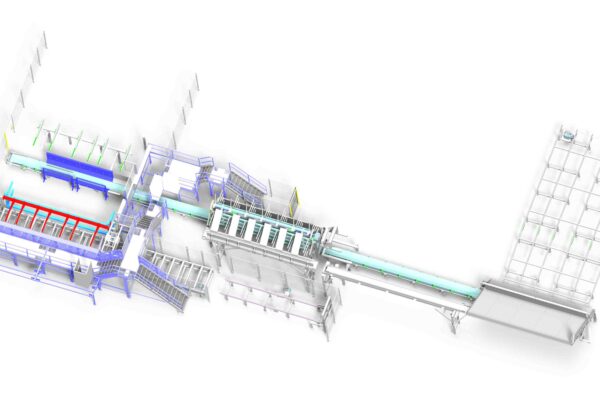

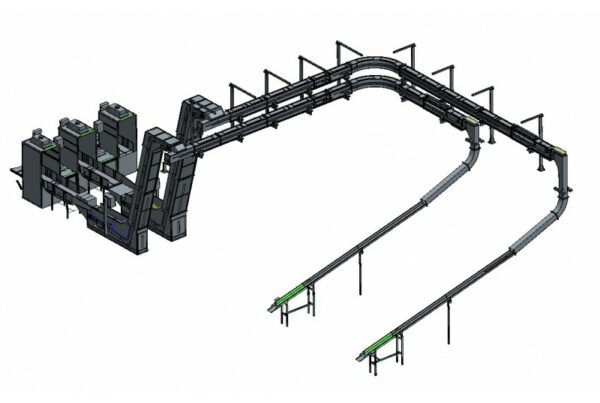

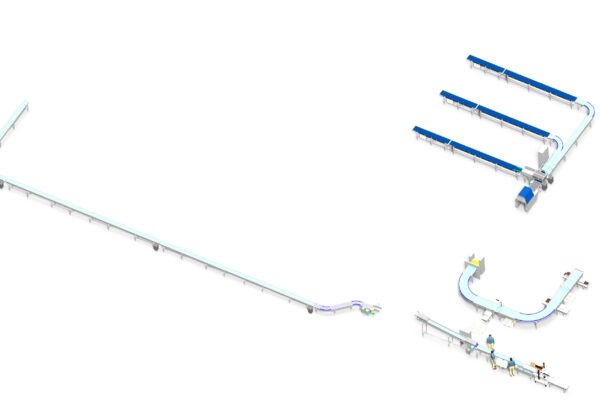

- Complete process line for transporting kitchen furniture

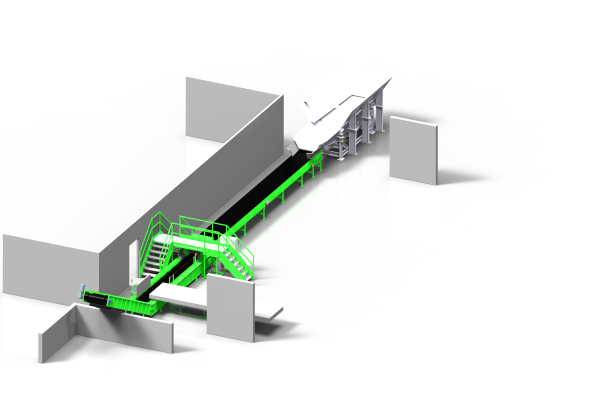

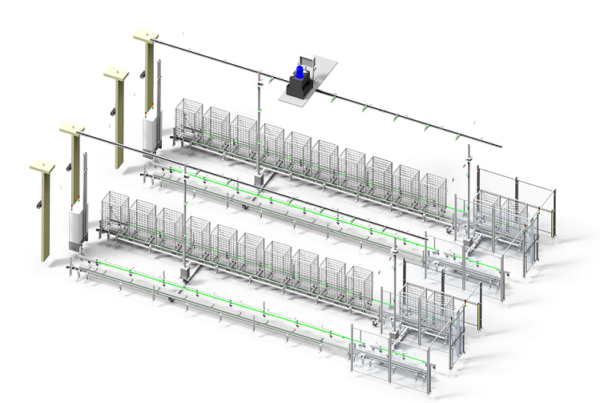

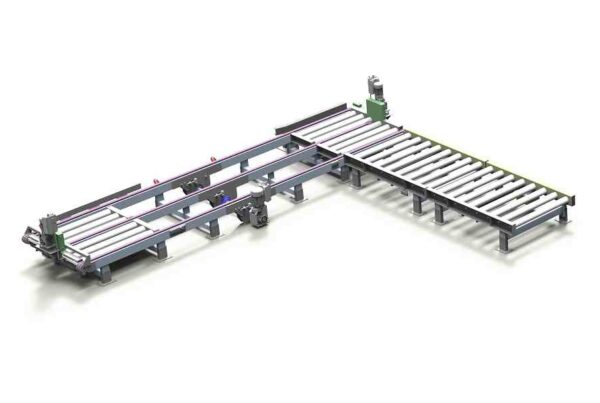

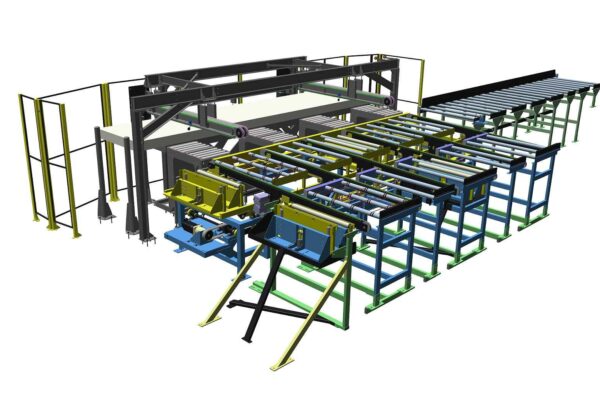

- Conveyor system for transporting pallets between two points

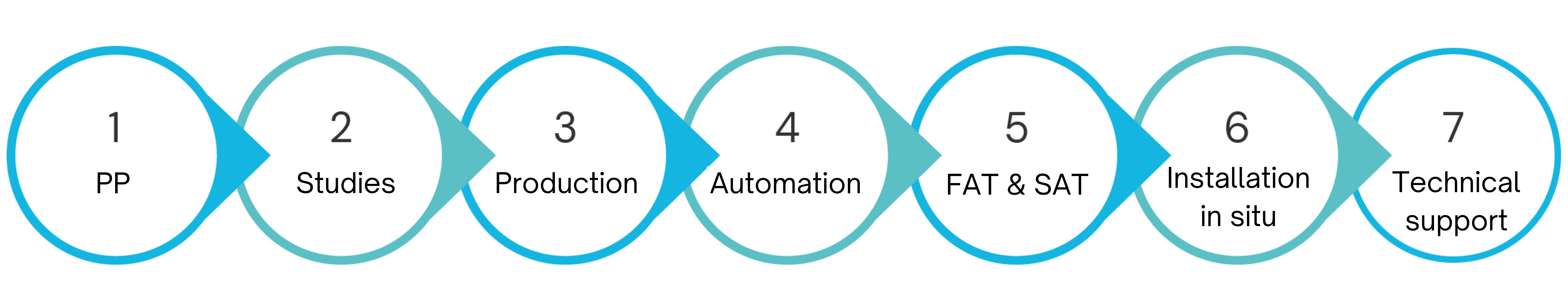

OUR PROJECT PROCESS

Chronology of your projects