We’ve been making bespoke industrial sheet metal parts at our production site in Castres for over 20 years. Our technical expertise enables us to design small and medium size parts, which we manufacture individually or in small series.

Our tailor-made processes are all carried out in-house from A to Z. We offer you a direct process, with just one contact person who will manage your entire project from conception to delivery.

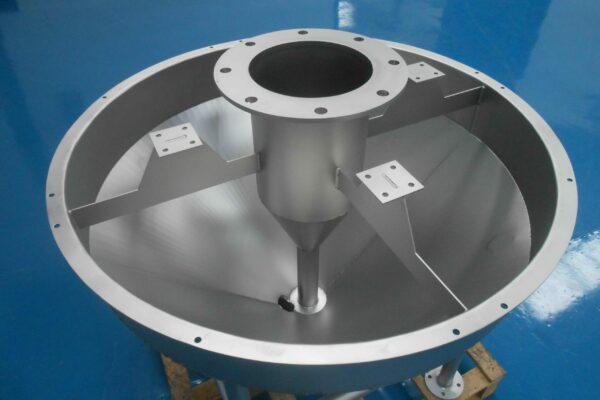

Our boilermaking workshop in Castres

Our boilermaking workshop designs industrial parts from sheet metal such as steel, stainless steel or aluminium.

Integrated in 1999 into the manufacturing workshops that we had already set up on our production site, our boilermaking workshop now comprises:

- 15 multi-skilled boilermakers and welders able to work on steel, stainless steel and aluminium,

- two apprentices,

- A folding operator

- A throughput operator

- A bead-blasting operator

- Two craftsmen for the finishing touches.

All our operators are qualified to carry out all welding operations required to manufacture our industrial boilerwork parts. Their know-how enables them to bring a wide range of skills to the fore in:

- Folding

- Working on a one-off or small series basis

- Clear cuts for food processing conveyors

- Precision bending using angle controllers

- Producing complex parts

Boilermaking at Benne SA:

Our expertise in boilermaking and industrial sheet metal work enables us to design specific equipment to manufacture our industrial conveyors. Sheet metal work is at the heart of our expertise in boiler making. This work involves the following operations:

- Cutting

- Drilling

- Folding

- Rolling

- Welding

Our expertise in boilermaking also means we are able to deliver finishing operations:

- Engraving

- Surface treatment:

- Bead blasting

- Powder coating

- Others can be done on request.

OUR PROJECTS