To guarantee material handling perfectly suited to their products, companies need to equip their production lines with industrial conveyors that are fully aligned with the specific issues associated with their activity sector. Conveyors are the most appropriate solution for handling a company’s goods in the best and safest way possible.

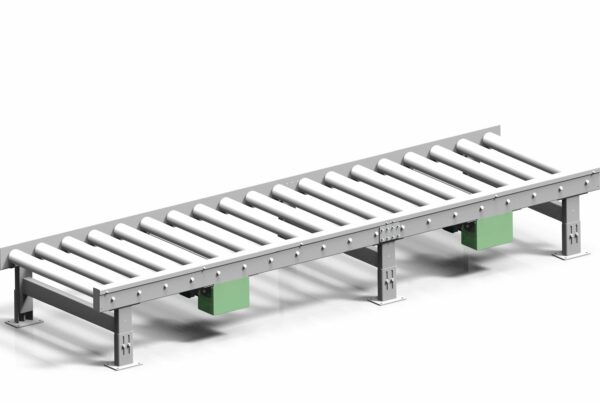

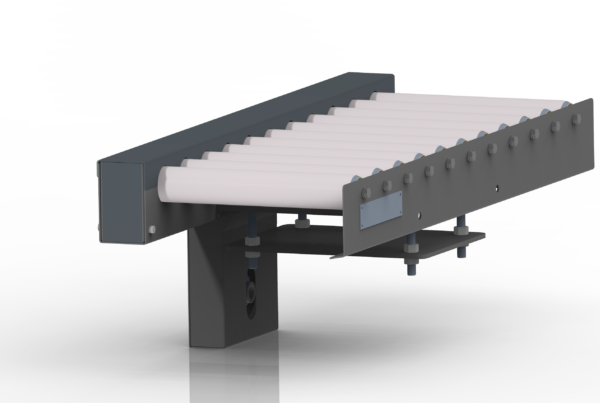

While belt conveyors are among the types most commonly found in warehouses, roller conveyors are also an essential conveyor system in all areas of activity. As experts in the manufacture of industrial conveyors for over 35 years, Benne SA offers many roller conveyor models in its standard range.