These belt conveyors (standard conveyors) have been greatly standardised and are suitable for many applications, including in the agri-food sector.

Their simple design enables rapid production and increased reliability for these types of conveyors.

We have taken care to provide a good level of quality and robustness, increasing the longevity of these models.

Benne SA: Conveyor Belt Experts Since 1985

Benne SA, a family-owned company based in Tarn, specializes in manufacturing high-quality conveyor belts. With nearly 40 years of expertise, the company offers a wide range of standard conveyors, including belt conveyors designed to meet the specific needs of your business.

How Does a Belt Conveyor Work?

A belt conveyor is an industrial transfer system used to transport various products from point A to point B. Essential in a logistics chain, it plays a key role in processes such as reception, production, storage, order preparation, and shipping.

The main components of a belt conveyor are:

- The conveyor belt, which transports the products.

- The drums (drive and return), supported by bearings or housings.

- The motor, which powers the belt’s movement.

The system operates through the friction between the belt and the drive drum, which is powered by the motor. The return drum, located at the opposite end, maintains the belt’s tension, optimizing friction and overall system performance.

Belt Conveyors: A Versatile Solution for All Industries

Benne SA’s belt conveyors are designed to adapt to a wide range of industrial sectors:

- Food processing and pharmaceuticals, where precision and hygiene are critical.

- Packaging, cardboard, textiles, automotive, woodworking, industrial machinery, and many others.

Using parametric 3D models (length, width, height), our conveyors offer exceptional durability and robustness, perfectly meeting the specific requirements of your business.

Types and Models of Belt Conveyors

We offer several models of belt conveyors, which can be integrated into complete conveyor lines. The two main types are:

- Straight belt conveyors: Ideal for transporting products in a straight line, these are the most common.

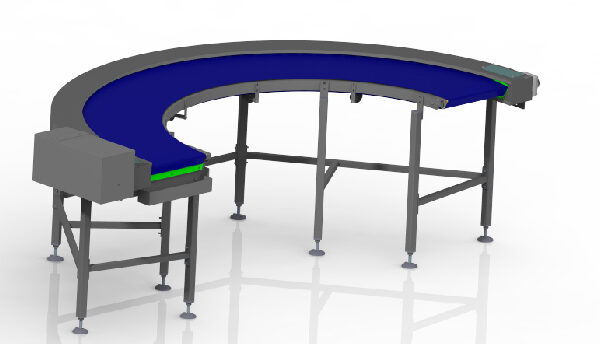

- Curved belt conveyors: Used to navigate around obstacles or optimize warehouse space.

Our Belt Conveyor Models

Straight belt conveyors:

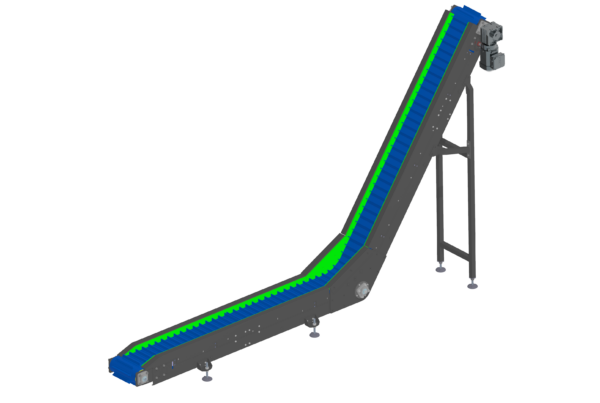

- Straight belt conveyor with trough

- Straight belt conveyor with inflection

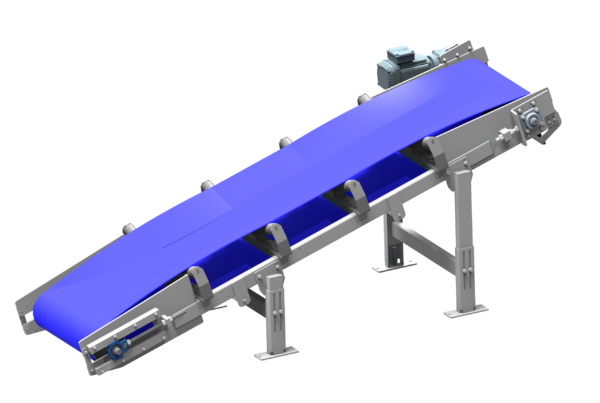

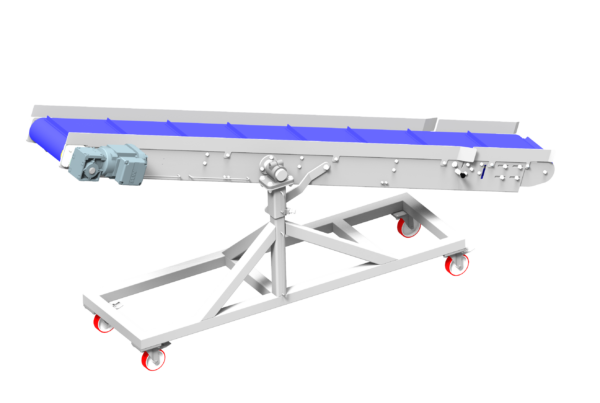

- Straight elevating belt conveyor

- Straight belt conveyor with cantilevered lift

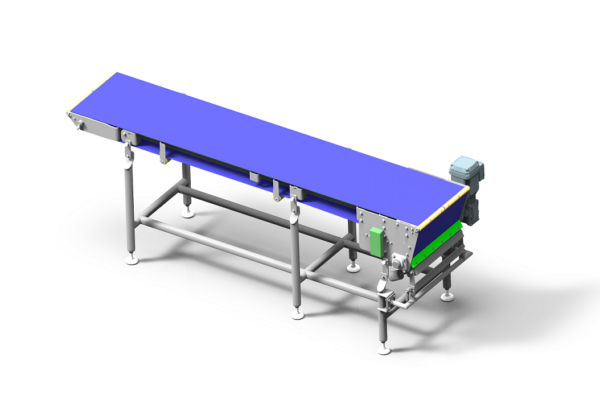

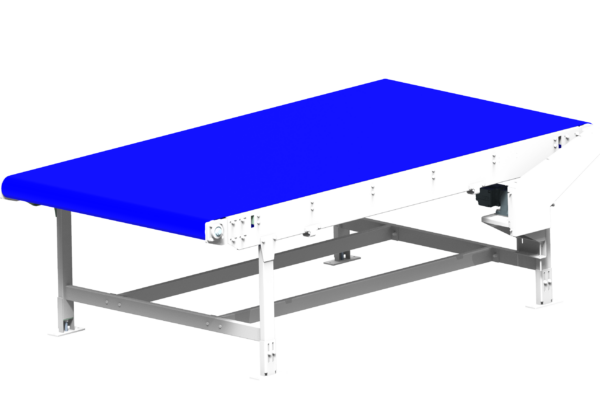

- Straight wide belt conveyor

- Straight belt conveyor with sabre

- Straight belt conveyor with barriers

- Straight belt conveyor with small rollers

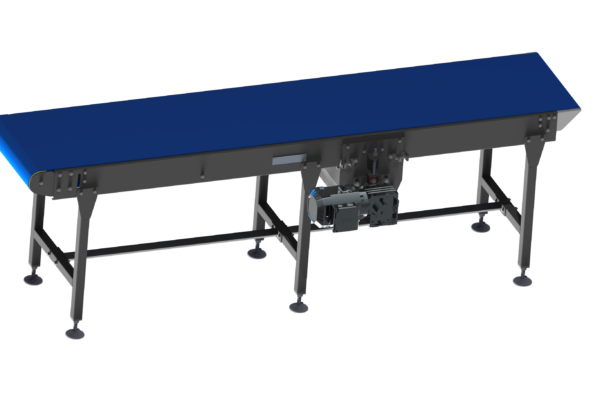

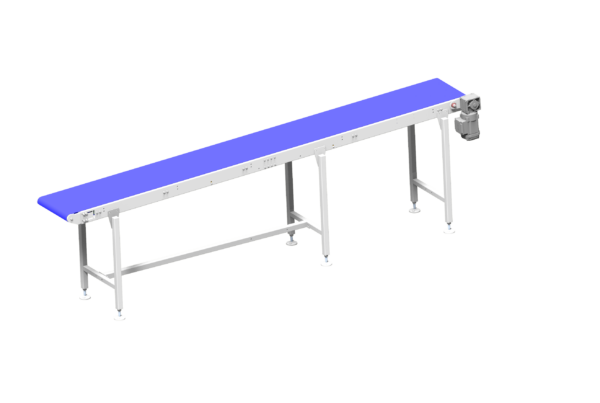

- Standard straight belt conveyor

Curved belt conveyors:

- Curved belt conveyor with sabre

- Standard curved belt conveyor

These varied solutions ensure that every business finds the perfect model to suit its specific industrial conveying needs.