A packaging line (also called a packing line) at an industrial site means a production line on which finished products are packaged (packed) for protection during subsequent handling. Packaging lines generally incorporate different packing systems such as taping machines, sealers, wrappers, palletising machines and cartoning machines.

An optimised packaging line enables you to improve your productivity, as the packaging of your finished products will be completely automated. Take advantage of our expertise in industrial handling by choosing one of our end-of-line conveyors to package your products.

How can you optimise your packaging lines ?

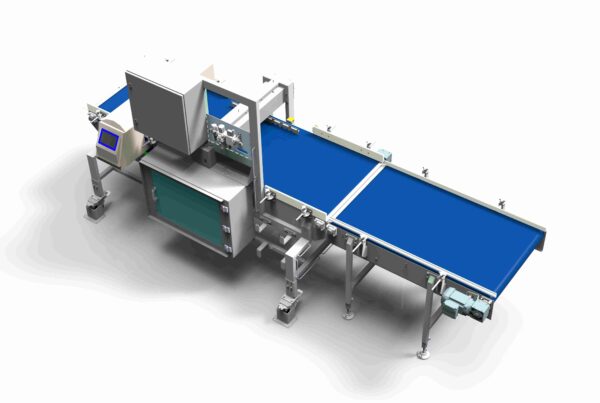

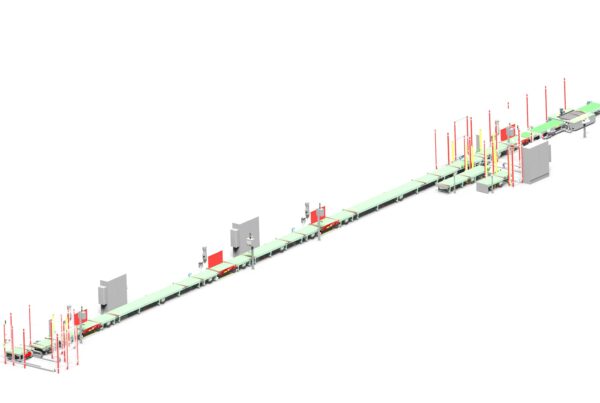

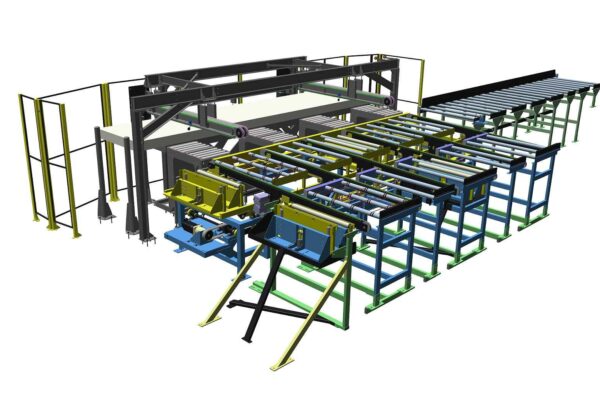

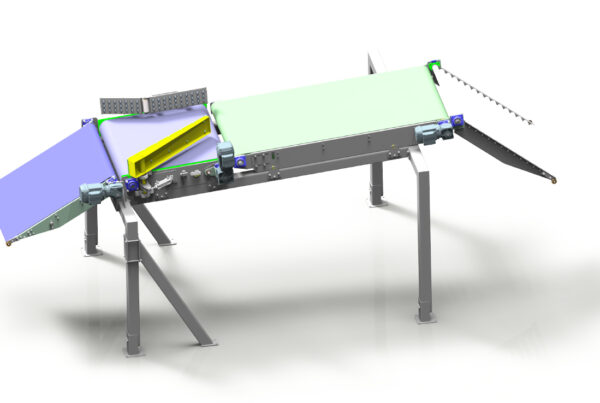

The best way of optimising your packaging lines is to complete your production lines with end-of-line conveyors tailored to the configuration of your site and your production targets. Creating these end-of-line systems will simplify the work of your operators thanks to increased automation of your production line. Fully automated and robotised, these line ends will also accelerate the manufacture of your products with safe, continuous operation.

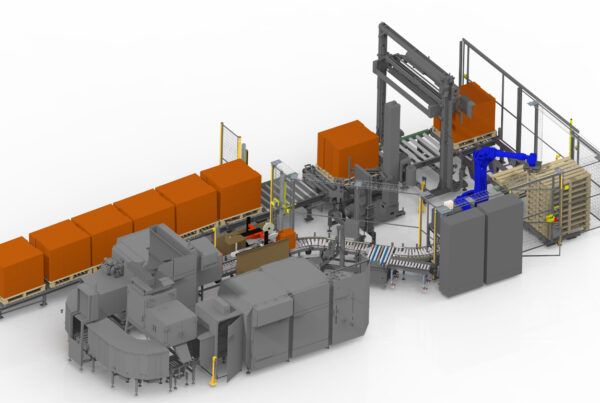

Benne SA can help you optimise your packaging lines by offering complete end-of-line models, which can incorporate various packing machines to package your finished products:

- Cartoning machine for putting your products in boxes

- Palletising machine for stacking your products on pallets

- Taping machine

- Sealer for palletised loads

- Wrapper to safeguard the handling of your products on pallet trucks

- Shrink-wrap packaging machine for wrapping batches of your products

Discover our packaging line solutions to improve your productivity

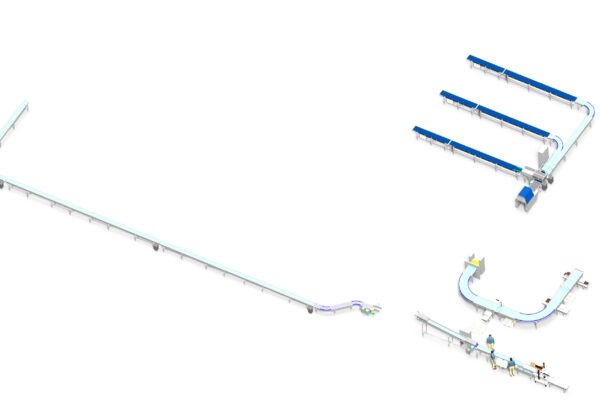

Our experience in building custom industrial conveyors enables us to offer you a wide range of conveyors to help you optimise your packaging lines. We are experts in designing end-of-line systems for:

- Labelling tyres

- Transporting empty cardboard boxes and cases

- Chocolate bar packaging

We can also offer our expertise in installing:

- A packaging line for baked goods

- A belt conveyor for transporting pizzas

- A box-filling conveyor in the agri-food sector to automate the cartoning of your products

- A conveyor for an insulation material inspection area

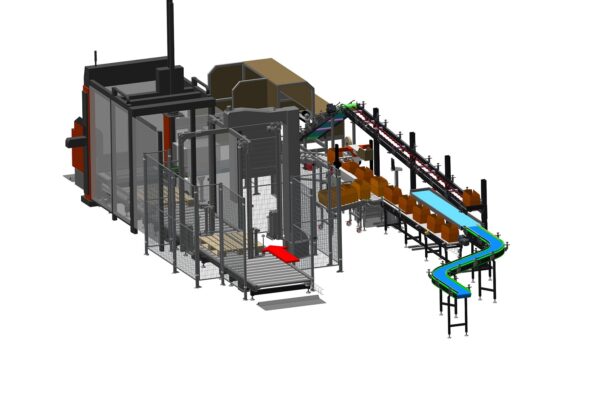

- A conveying system incorporating an end-of-line system to package and transport soap pearls

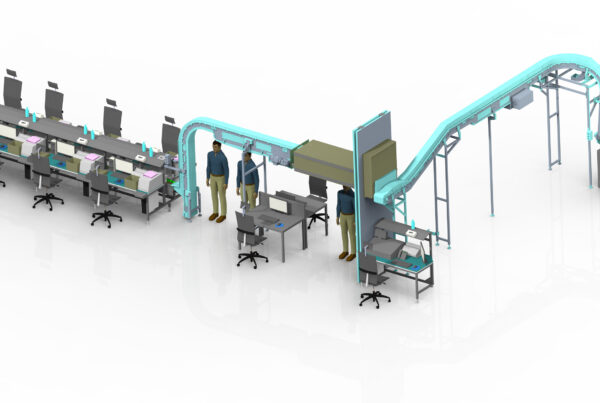

- A packaging line incorporating workstations to carry blood samples

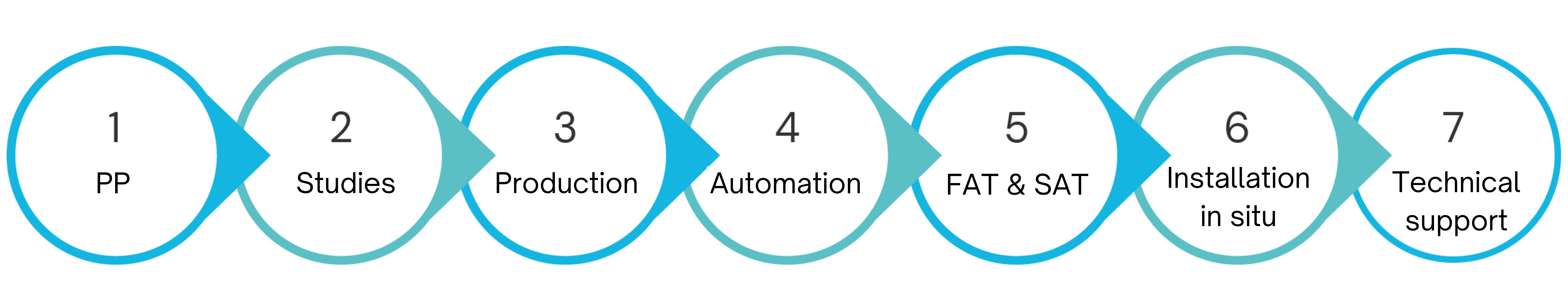

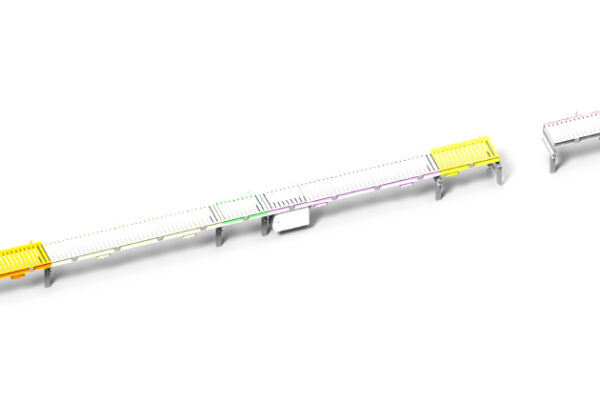

Our soap pearl conveyor is a packaging line incorporating several machines to pack your products (box former and closer, weighing machine, taping machine, labelling machine and wrapper). This packaging line can be used for small products in the chemical industry, but it can also be adapted for use in the agri-food or pharmaceutical sectors by optimising the packaging belts.

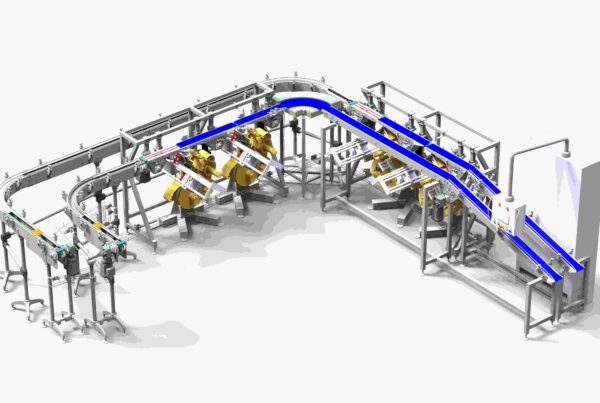

OUR PROJECT PROCESS

Chronology of your projects