Companies have long relied on the progress offered by robotics to guarantee the efficiency of their production lines. Contributing to the automation of industrial production lines, robotic integration now offers many possibilities for responding to industrial handling problems in various industrial sectors.

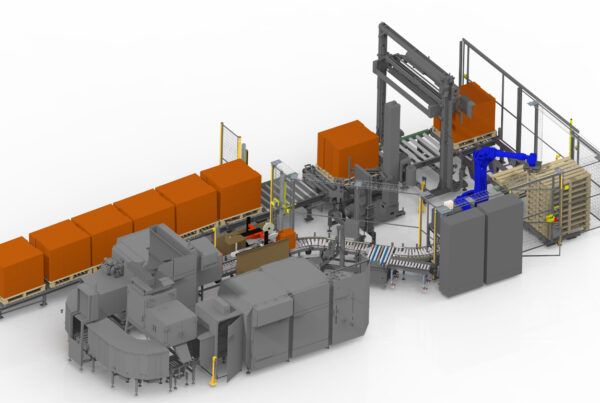

Specialising in the design of conveyor solutions suited to all industrial sectors, Benne SA supplements its range of custom industrial conveyors with a robotics integration service dedicated to automating your production lines.

Robotic integration to serve industrial handling

The purpose of an industrial conveyor line is to facilitate the transport of goods from one end of the production chain to the other. Any production line implies the execution of repetitive handling tasks to ensure product transport. As these tasks can be laborious for human operators to fulfil, companies systematically integrate robots into their production lines.

As the term suggests, robotic integration involves incorporating robots into a production line to automate certain tasks and make the operators’ work easier. Underlying the automation of production processes, robotic integration makes it possible to respond to several industrial handling problems. Robotic integration means goods can be routed more efficiently while making the production line safer.

Within a production chain, robotic integration can be either industrial or collaborative. In the first case, integrated robotic systems simply automate the most repetitive tasks. This generally involves multi-axis robot arms that are programmed to carry out precise tasks instead of operators.

In the case of collaborative robotic integration, the robots incorporated into the production chain carry out tasks while interacting with operators. Also known as “cobots”, these robots are easier to program than conventional industrial robots but can still carry out complex tasks.

Designed to work alongside human operators, “cobots” are always equipped with sensors to detect the presence of technicians and are programmed to stop if a situation presents a direct danger to someone nearby.

Benne SA, the expert in robotic integration to optimise your production lines

Complementing its expertise in industrial handling, Benne SA is also skilled in robotic integration. We can incorporate robots into your production lines, adapting perfectly to your various industrial handling problems.

To achieve this robotic integration, we draw on a range of robots and “cobots” designed to guarantee the efficient, safe handling of your products. Our range includes:

- A six-axis poly-articulated robot that is mainly found at the end of the production line

- The two-axis SCARA robot, used for small robotic integration applications

All the robots we offer for integration into your production lines are programmed and tested at our workshops in Castres to guarantee high-quality automation. We can also work directly at your production site to integrate a robot into your pre-existing conveyor lines.