At Benne SA, our expertise passed down through the generations is our strongest asset.

Our painting department responds to customers’ needs every day.

Their secret weapon? Their expertise and their ability to satisfy customer demand to the full.

At Benne SA, our expertise passed down through the generations is our strongest asset.

Our painting department responds to customers’ needs every day.

Their secret weapon? Their expertise and their ability to satisfy customer demand to the full.

To achieve this, they use several production processes to ensure high-quality results.

When they receive a part, our painters hang them from hooks suspended from rails. Whether the part is made of steel, stainless steel, aluminium or galvanised steel, the process is the same.

Once this step is complete, our experts clean the parts.

Large parts are cleaned with pressure washers. First, the parts are sprayed with a degreasing agent, which is then rinsed off with hot water and then cold water.

For smaller parts, we use the eco-jet method. What does this involve?

It is fairly similar – two minutes of spraying with degreaser and seven minutes of spraying with a product that makes the part electrostatic. This helps the paint particles to adhere to the part. Finally, the parts are blow-dried.

After the cleaning process comes the heating. The parts are completely dried in an oven at 150°C for around 10 to 15 minutes.

This preparatory stage is vital for a high-quality finish.

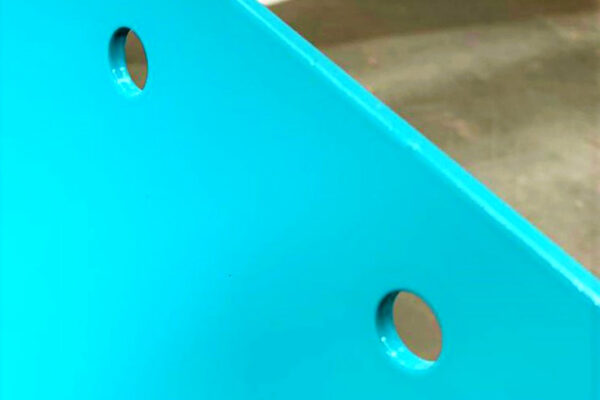

Next comes the painting stage. We use a powder painting process. We spray the parts with a paint spray gun using the powder coating technique.

We can paint your sheet metal parts in any colour you want. Given the variety of choice offered by our colour palettes, we can meet any need.

Satin finish, fine matt structured finish, gloss finish – you will be spoilt for choice!

Once the parts have been painted, they return to the oven at 190°C for around 20 minutes to cure the paint. This homogenises the paint and ensures a uniform finish.

When they leave the oven, we let the parts cool and then package them.

We never forget that high standards and quality are essential values for the company. This is why we always carry out quality control before dispatch. Using a measuring instrument to check the paint coating, we make sure the paint has been applied correctly.

MICRO-BEAD BLASTING

The micro-bead blasting process uses a nozzle to spray tiny glass beads measuring 25 hundredths of a millimetre at the stainless steel or aluminium to strike the surface and give the part a uniform finish.