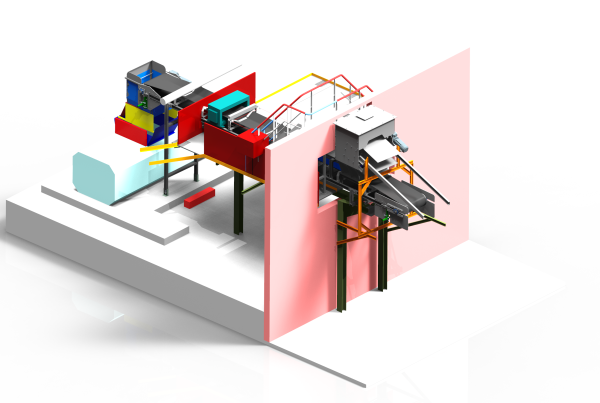

When it comes to 90° motorised roller conveyor technologies, there are multiple methods for transmitting the driving force between the rollers (slave transmission):

- The tangential belt enables products to accumulate but is limited in terms of drive strength and length.

- Chain bracelet: simple and effective, and very widely used.

- Round belt bracelets: less and less used because of limited drive power.

We can also distinguish between two motor variants for these conveyors:

- The use of traditional gear motors, 400 volts or 230 volts three-phase.

- 24-volt gear motors integrated into the body of the roller, the “motor roller”.

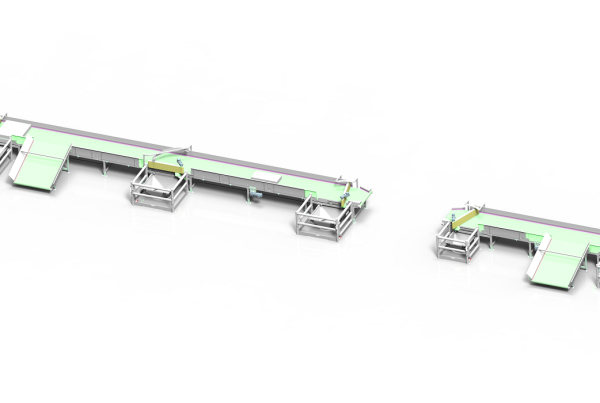

Many optional functions can be added to these conveyors:

- Pneumatic pushers.

- Tip or pivot rollers.

- Online reversal system.

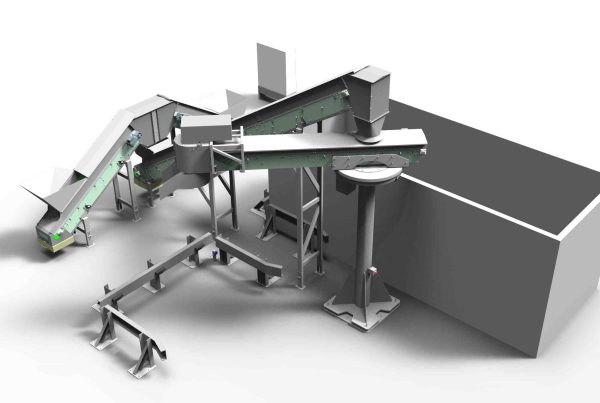

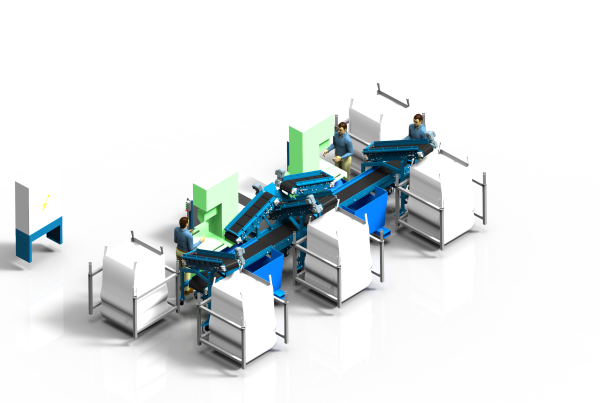

Driven conical roller conveyors are useful for changing the direction of transport lines.

These conveyors are subject to dimensional constraints due to the standardisation imposed by the suppliers of these rollers.