For many years now, companies have been relying on the advances offered by robotics to guarantee the efficiency of their production lines. By promoting the automation of industrial production lines, robotic integration now offers a wide range of possibilities for different sectors of industry to meet their industrial handling needs.

BENNE S.A. specialises in the design of conveyor solutions tailored to all industrial sectors. In addition to its range of customised industrial conveyors, the company also offers a robotics integration service dedicated to the automation of your production lines.

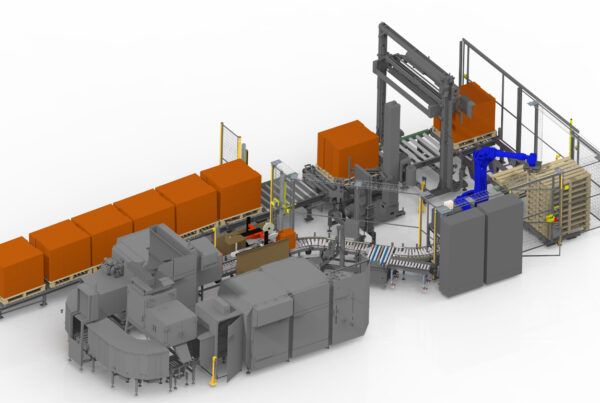

Robotic integration for customised industrial handling systems

The purpose of an industrial conveyor line is to facilitate the transport of goods from one end of the production line to the other. Every production line involves repetitive handling tasks. These tasks can be difficult for human operators to perform, which is why companies are integrating robots into their production lines.

Within a production chain, robotic integration can be industrial or collaborative. In the first case, integrated robotic systems simply automate the most repetitive tasks. These are usually multi-axis robotic arms, programmed to carry out specific tasks in place of operators.

In the case of collaborative robotic integration, robots integrated into the production line perform tasks in interaction with operators. Also known as ‘cobots’, they are generally easier to program than industrial robots, yet can perform equally complex tasks.

Designed to work with human operators, cobots are equipped with systems capable of detecting the presence of employees, and are programmed to stop if a situation presents a direct danger to a person in the vicinity.

BENNE SA, experts in robotic integration to optimise your production lines

In addition to its expertise in industrial handling systems, BENNE S.A. also has expertise in robotic integration, enabling us to offer increasingly comprehensive services in the field of materials handling.

We can integrate a wide range of robotic applications on your lines.

All the robots we propose for integration on your production lines are programmed and tested in our workshops in Castres, to guarantee high-quality automation. We can also intervene directly on your production site to integrate a robot on your existing conveyor lines.

Conveyor for transporting soap pearls

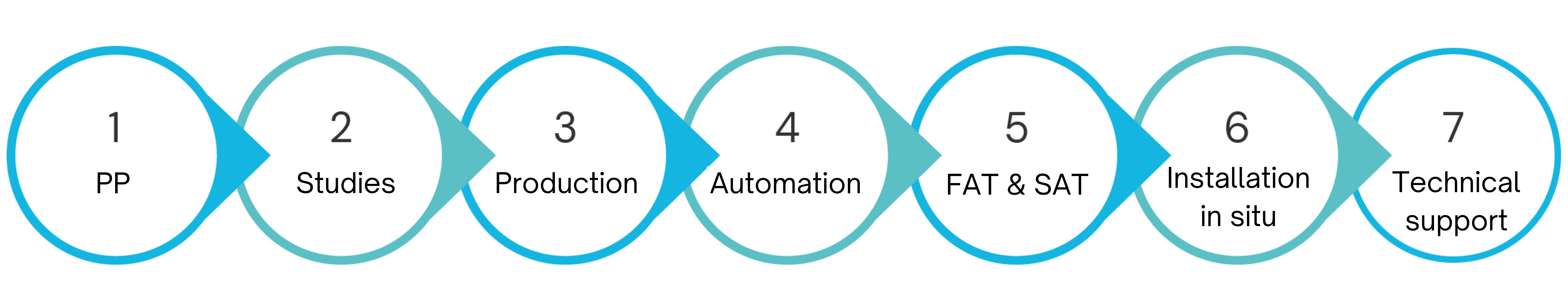

OUR PROJECT PROCESS

Chronology of your projects