Discover our packaging line solutions to improve your productivity

A packaging line is a set of technical resources used to group together one or more product flows to route them in a controlled manner to systems or functions that add value to these products, essentially in terms of their physical state when they are marketed.

Automated packaging lines are of major interest to all industries that produce in large quantities.

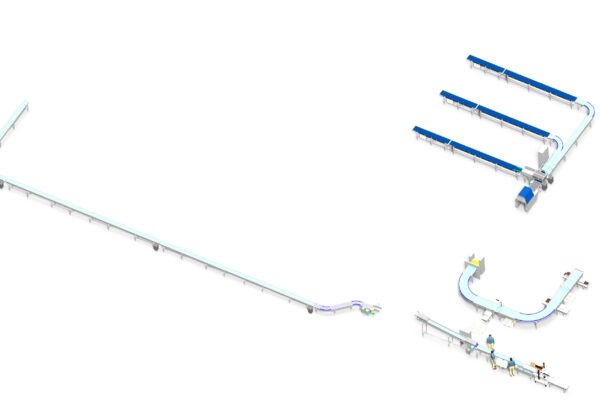

Our experience in the manufacture of made-to-measure industrial conveyors enables us to offer you a number of examples of how we can optimise your packaging lines.

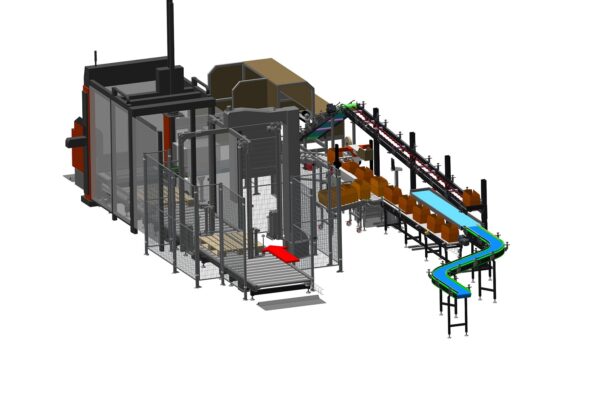

A pastry packaging line

A belt conveyor for transporting pizzas

A conveyor for filling cartons in the agri-food sector, to automate the packing of your products into cartons

An inspection zone conveyor for insulating materials

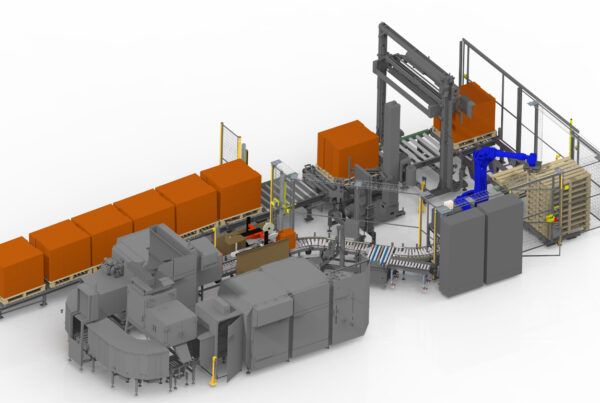

A conveyor system with integrated end-of-line for packaging and transporting soap beads

A packaging line with integrated workstations for transporting blood tubes

Conveyor for transporting soap pearls

Chocolate bar packaging

Packaging line for baked goods

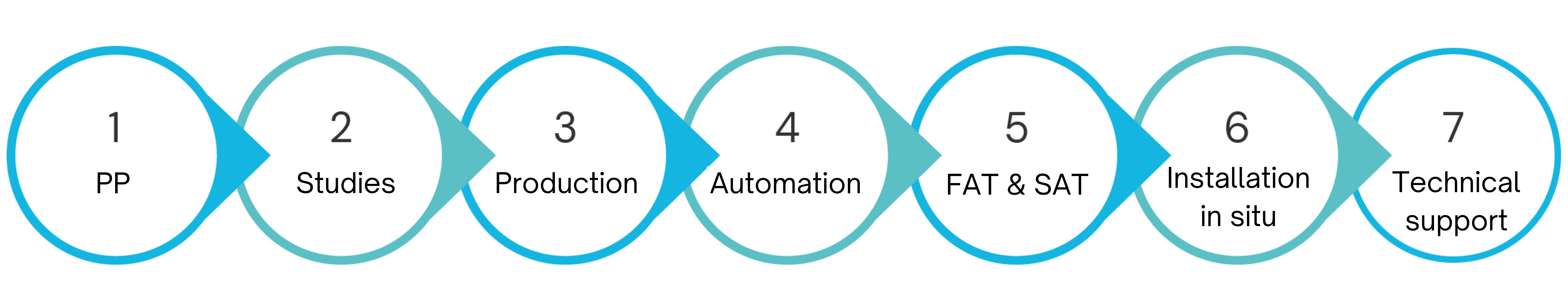

OUR PROJECT PROCESS

Chronology of your projects