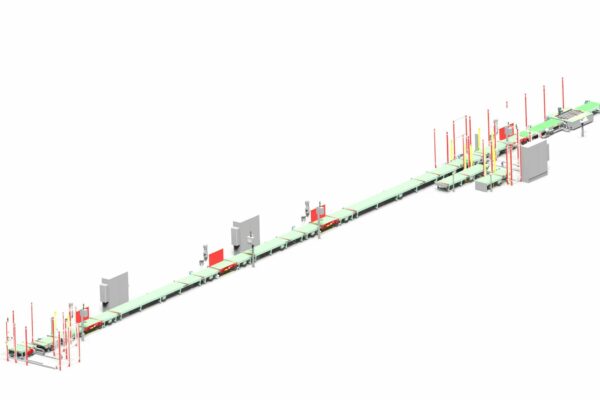

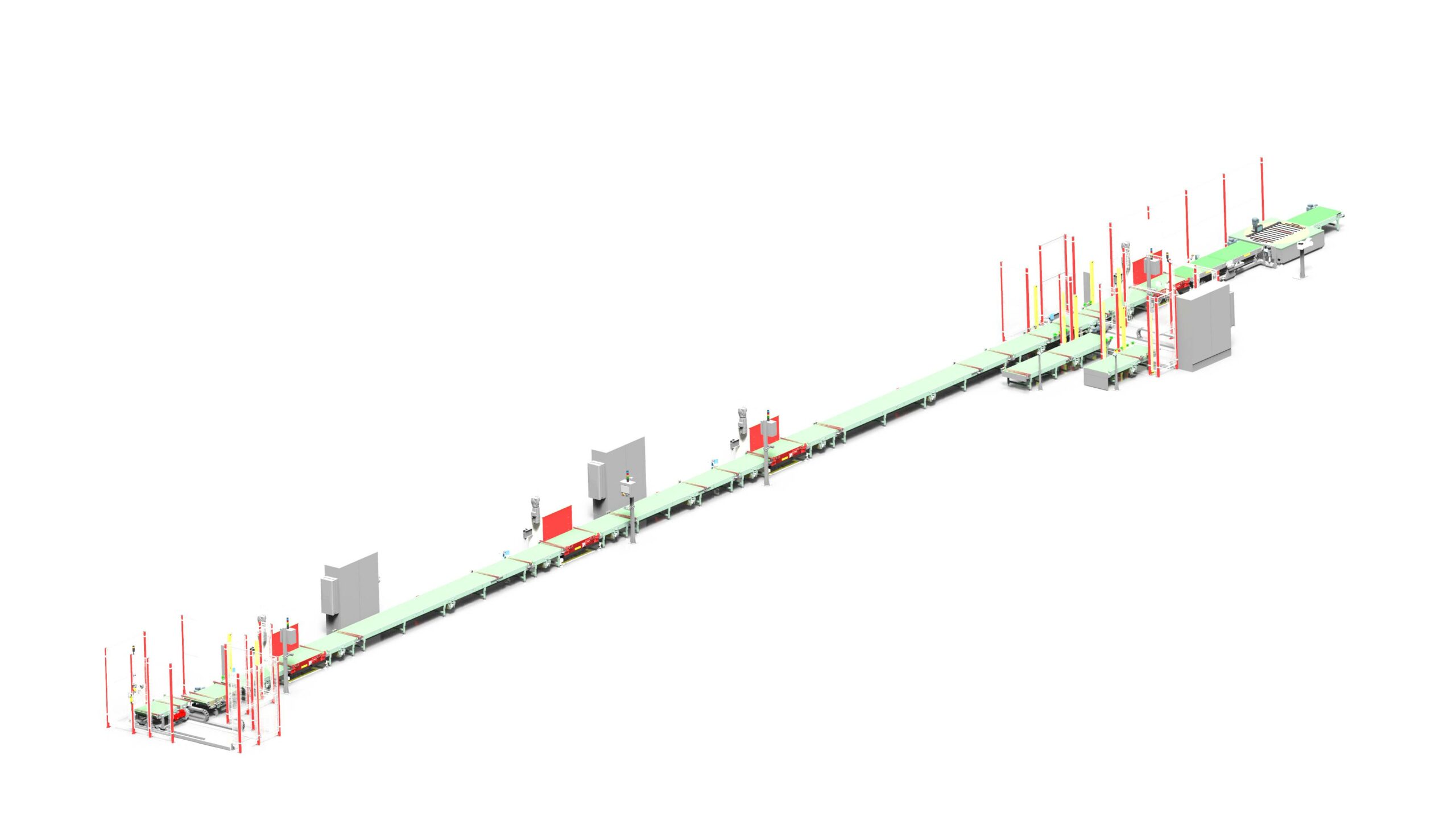

Conveying and handling of furniture for accessorisation

Project summary:

The purpose of this installation is to convey and handle furniture so that it can be accessorised.

Technical description:

There are 6 zones laid out as follows:

- “Start of line” zone

- A rail guided shuttle with a straight central-drive double-knife-edge belt conveyor

- A turntable equipped with a straight central-drive double-knife-edge belt conveyor

- A straight knife-edge belt conveyor

- “Access station 1” zone

- Three straight knife-edge belt conveyors

- A lift with its straight knife-edge belt conveyor

- “Access station 2” zone

- Three straight knife-edge belt conveyors

- A lift with its straight knife-edge belt conveyor

- “Access station 3” zone

- Three straight knife-edge belt conveyors

- A lift with its straight knife-edge belt conveyor

- “Repair station” zone

- Three straight knife-edge belt conveyors

- A rail guided shuttle

- Straight central-drive double-knife-edge belt conveyor on the shuttle

- “Packing station” zone

- A straight knife-edge belt conveyor

- A lift with its straight knife-edge belt conveyor

- A turner with two straight belt conveyors

A turntable with a straight roller conveyor

- A straight belt conveyor

Technical data:

- Products: Kitchen furniture

- Product weight: Variable

- Product size: Variable

- Rate: The target rate of the line is 45 items/hour, giving a takt time of 1 min 20 secs/item of furniture

- Number of hours of operation per day: 2 x 8 hours – 5/7 days

- Environment: Standard