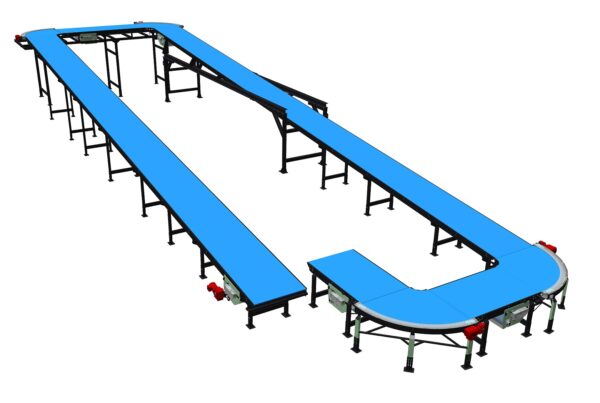

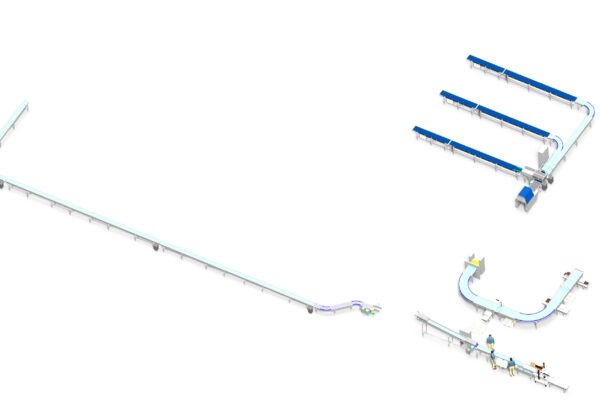

A complete line is a production line that can be used for packaging, inspection, order preparation, palletising and IQF. A complete line groups together different industrial conveyors depending on the handling needs of the company’s business.

All lines are not identical, but depend on the specific needs of a company’s business. Benne S.A. offers you its expertise in industrial handling systems to design complete lines and conveyor systems tailored to the needs of your industrial site.

Benne SA, designer of complete process lines for industrial handling

As a designer and manufacturer of specific and customised conveyors for industrial handling, Benne S.A. is able to find conveyor solutions tailored to your needs. Our complete lines are assemblies of off-the-shelf machines combined with our conveyors to meet your needs. They are all designed and manufactured in our workshops in Castres by our engineers and qualified technicians. This continuity in the design and manufacture of our complete lines enables us to guarantee the total reliability of all our lines.

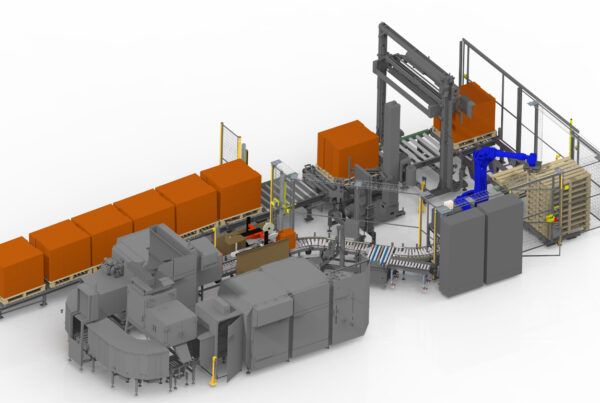

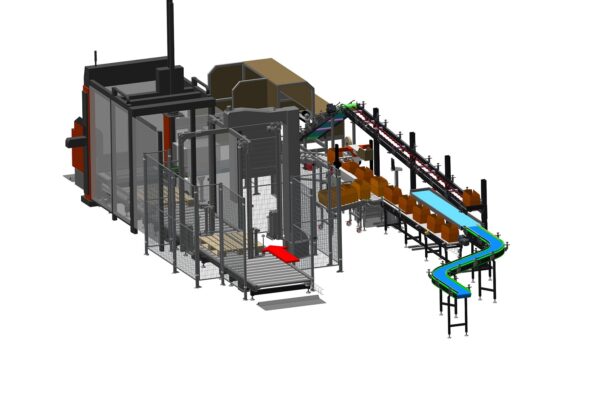

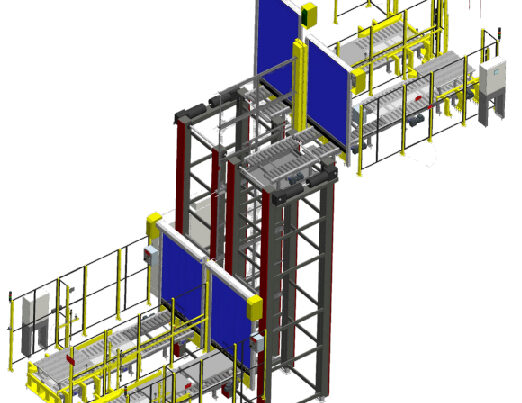

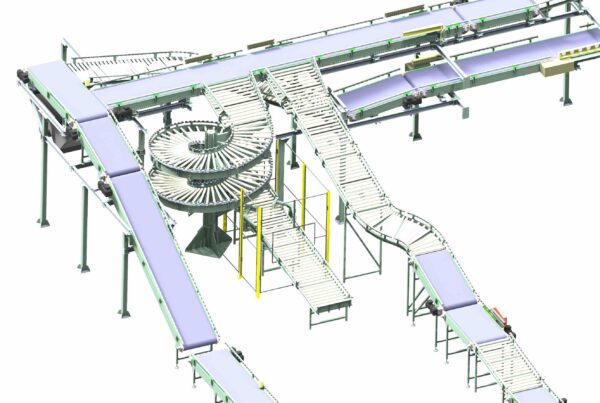

Our complete lines are not simply an assembly of standard industrial conveyors forming a complete production line. They are systematically made-to-measure industrial conveyors tailored to the needs of your sector of activity, incorporating automation developed in-house. Our complete lines can also include many specific features to meet your industrial requirements. The specific features of our complete lines include the integration of robotics, dosers, weighers, metal detectors, labelling, marking, etc., as well as the creation of new industrial handling solutions. All these adaptations to our conveyor systems enable us to create complete lines for every company, whatever its sector of activity.

Discover our many complete process line projects

Our expertise and our ability to adapt our conveyor systems to your specific needs enable us to design complete lines for all sectors of activity. We work closely with the food and pharmaceutical industries, as well as the packaging, cardboard, textile, automotive, furniture and chemical sectors.

Thanks to Benne S.A., you can find a turnkey conveyor solution tailored to your needs, to create a complete line that perfectly meets your expectations. Create your complete customised line from our range of industrial conveyors:

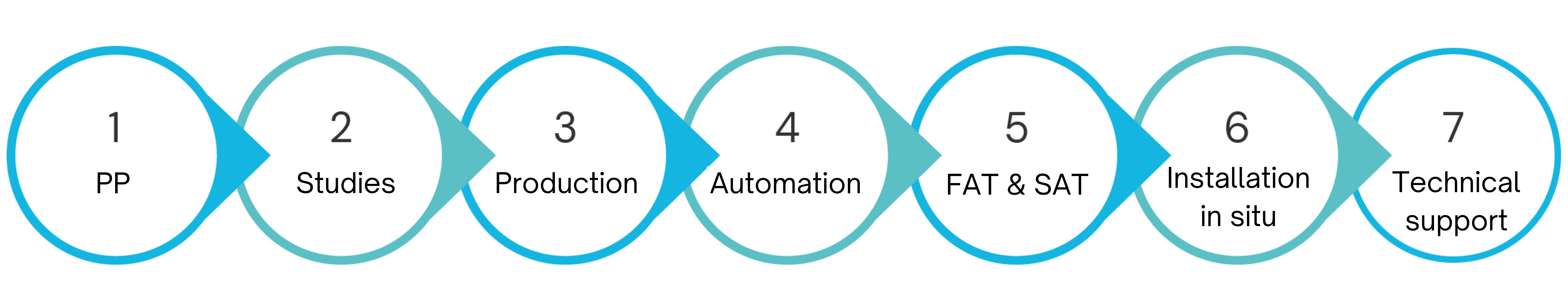

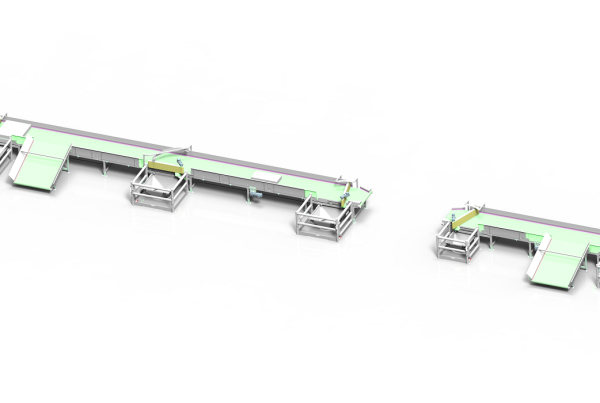

Complete line of conveyors for transporting plastic trays

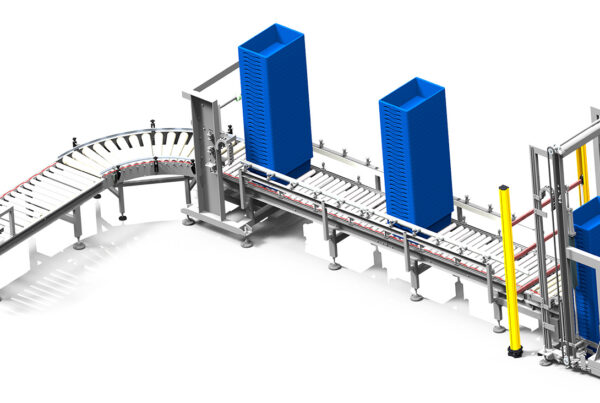

Complete process line for transporting kitchen furniture

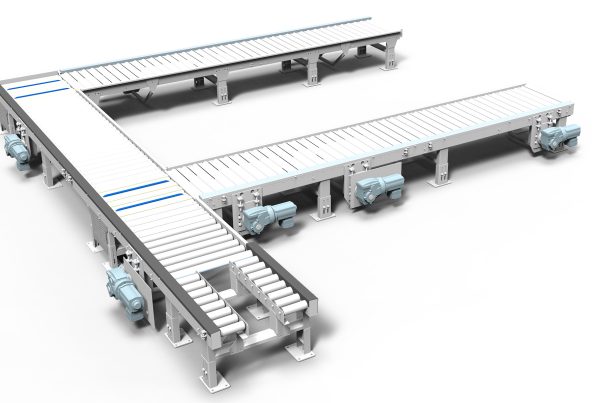

Conveyor systems for transporting pallets

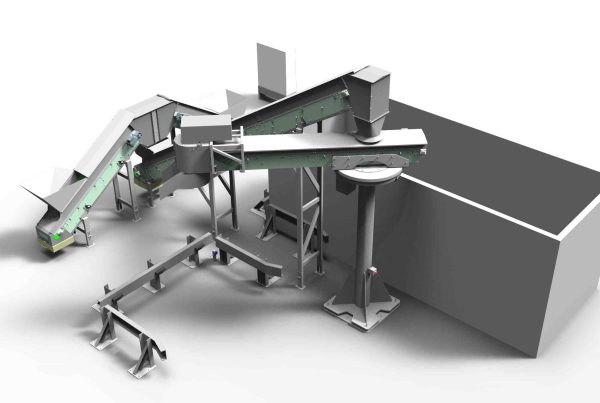

Conveyor systems for transporting powder and granules

Conveyor systems for transporting bare products (meat, fish, confectionery)

Bin destacker for hospital pharmacies

Conveyance and destacking of Intermediate Bulk Containers

Conveyors for pharmaceutical environments

Motorised roller and chain conveyors with square take-up

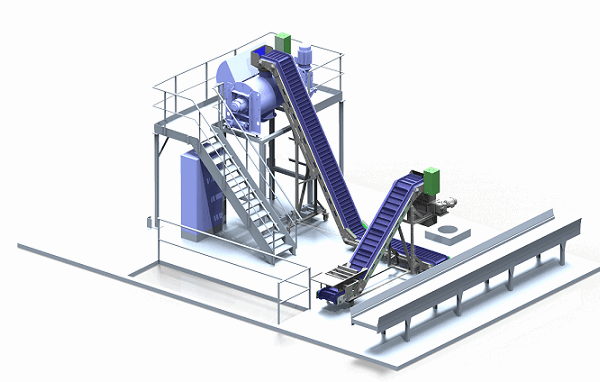

Wide belt conveyor for feeding hemp bales to digesters

Optimization and filling of skips via conveyors

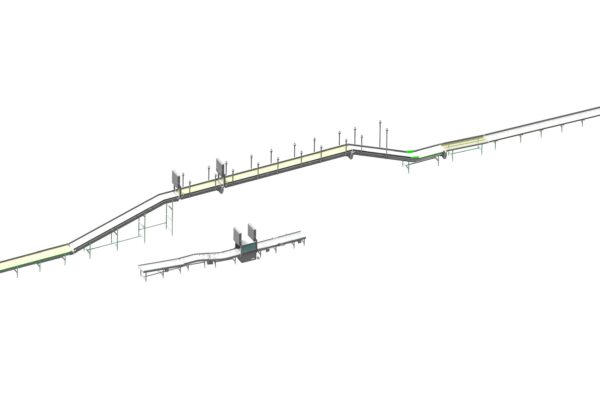

Positive drive belt conveyors with low inflection. Stainless steel version for the food industry.

Modular belt and roller conveyor line

Conveyor for transporting soap pearls

Chocolate bar packaging

Transporting bags of laundry

Transport and storage of rubber pallets

Knife-edge belt conveyor for cookies

Packaging line for baked goods

Automatic conveyor system for tyres

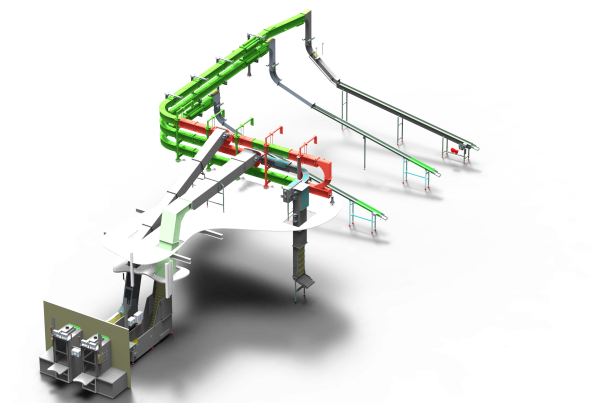

OUR PROJECT PROCESS

Chronology of your projects