Conveyor system for transporting and checking blood samples

Summary:

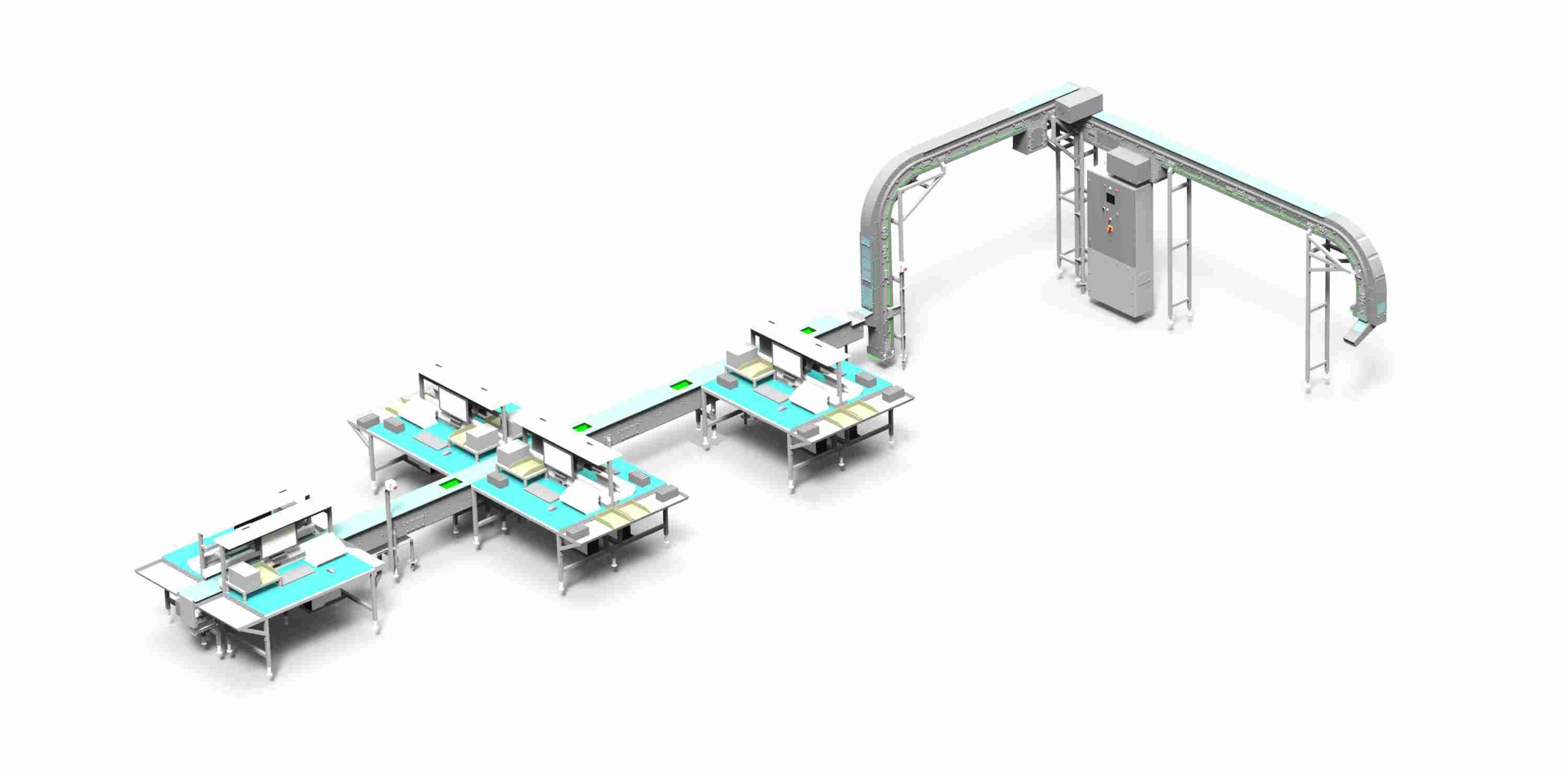

The goal of this project is to install a complete system for routing tubes of blood from the reception testing stations to the new testing machine.

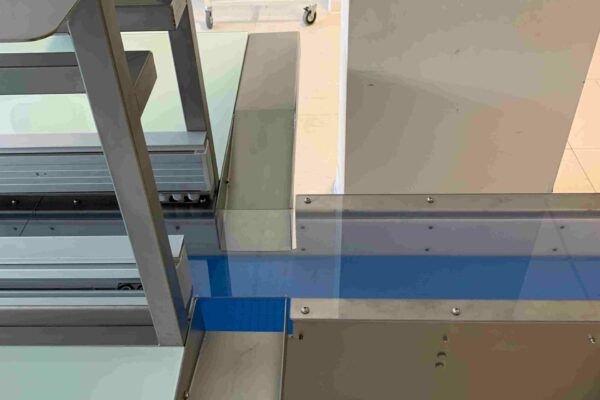

The operators place the tubes on the conveyor at table CV1, and the tubes are then carried along the inclined conveyor CV2. The inclined conveyor transfers the tubes between the two rooms and places them on conveyor CV3. Conveyor CV3 completes the tubes’ journey to the new testing machine.

Technical description:

Conveyors used for the project:

- One driven-belt conveyor

- One straight high-angle modular belt conveyor

- One 90° curved modular belt conveyor

- Two workbenches with stainless steel structures

- 10 stainless steel ergonomic screen and keyboard supports

- 10 stainless steel ramps for the tubes

- One conveyor integrated into the table

- Complete electrical system

Technical data:

- Products transported: Sealed plastic tubes containing blood

- Weight of transported product: 50 grams

- Size of transported product: -16 x 100 mm, -13 x 100 mm and -13 x 75 mm

- Transport direction: Bulk

- Rate: 15 m/min

- Number of hours of operation per day: 2 x 24 hrs

- Temperature: Ambient (5°C to 40°C)

- Environment: Dry

- Cleaning: Dry cloth

Application:

This kind of project is particularly used in the pharmaceutical industry. It is a conveyor system that can be adapted for other activity sectors, transporting tubes or other small products.