A conveyor becomes specific when it has to undergo a certain number of modifications to provide the required functions. In some cases, it may be necessary to design the conveyor from the ground up.

Our ‘engineering’ sales department and design offices are able to take into account the characteristics of your products and projects, in order to determine the type of conveyor best suited to solving the problem.

Naturally, we can draw on our extensive database to modify, remodel, combine and customise tried-and-tested systems and design new ones.

'.get_the_title().'

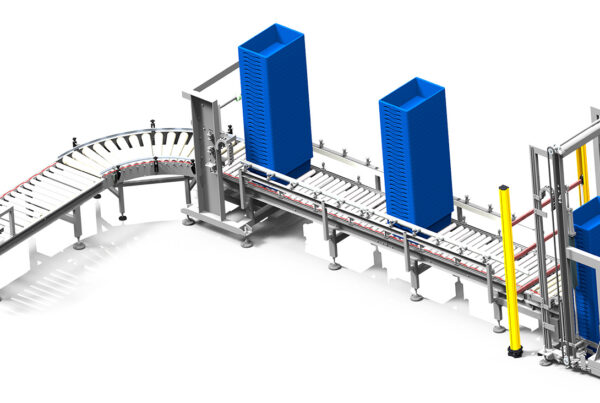

Bin destacker for hospital pharmacies

'.get_the_title().'

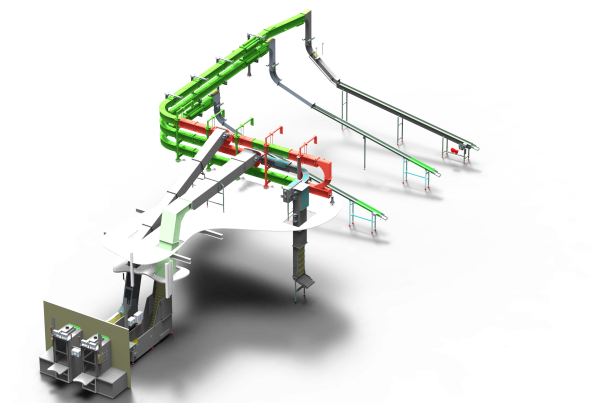

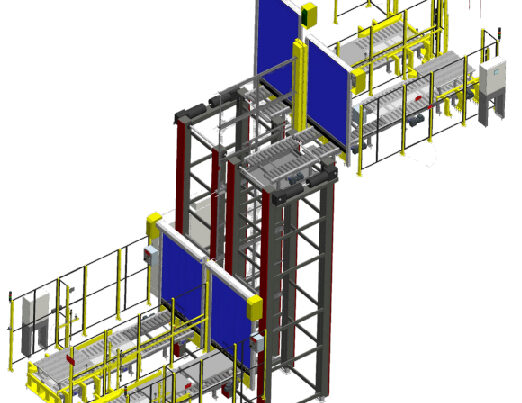

Conveyance and destacking of Intermediate Bulk Containers

'.get_the_title().'

Conveyors for pharmaceutical environments

'.get_the_title().'

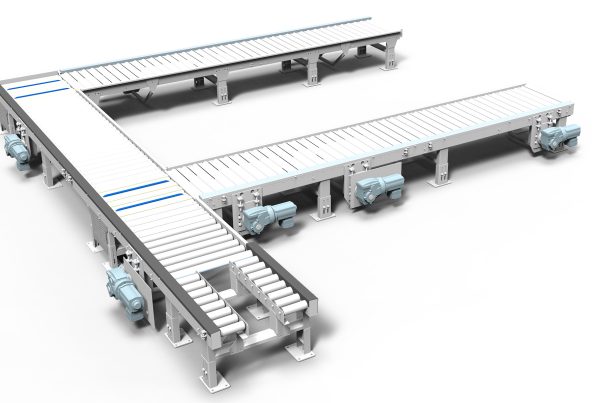

Motorised roller and chain conveyors with square take-up

'.get_the_title().'

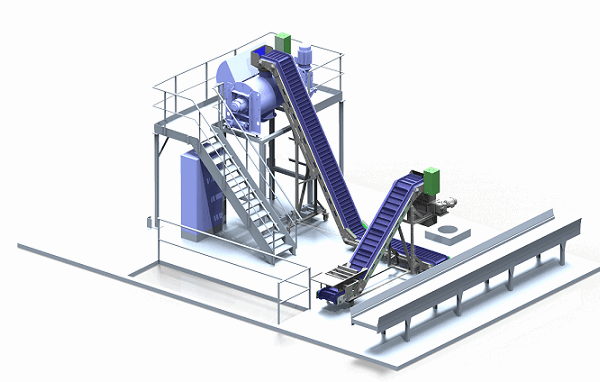

Wide belt conveyor for feeding hemp bales to digesters

'.get_the_title().'

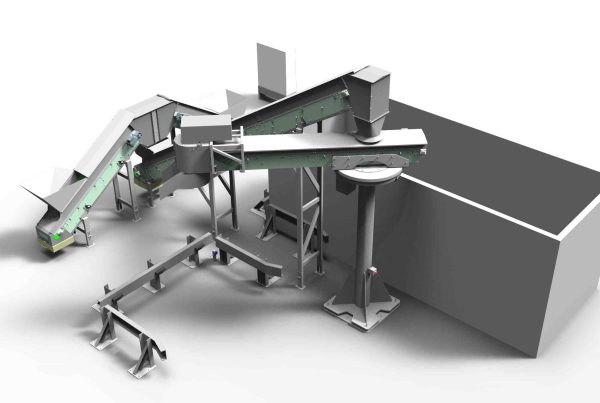

Optimization and filling of skips via conveyors

'.get_the_title().'

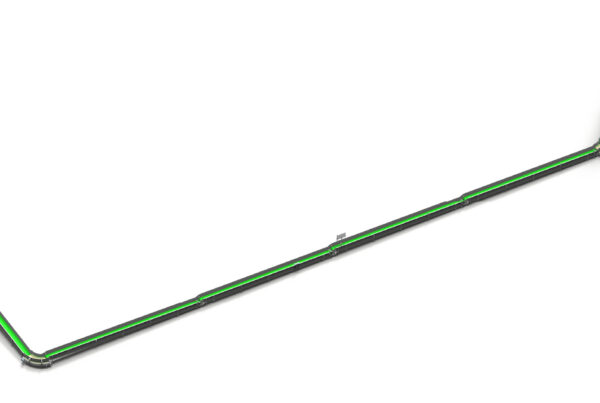

Positive drive belt conveyors with low inflection. Stainless steel version for the food industry.

'.get_the_title().'

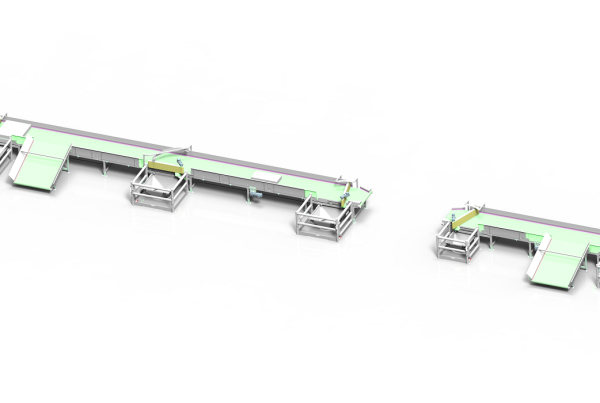

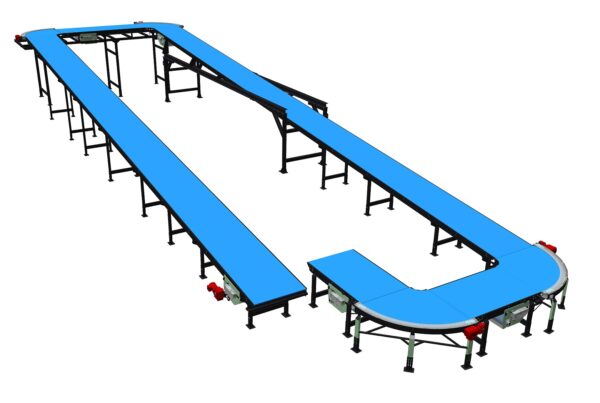

Modular belt and roller conveyor line

'.get_the_title().'

Conveyor for transporting soap pearls

'.get_the_title().'

Chocolate bar packaging

'.get_the_title().'

Transporting bags of laundry

'.get_the_title().'

Transport and storage of rubber pallets

'.get_the_title().'

Knife-edge belt conveyor for cookies

'.get_the_title().'

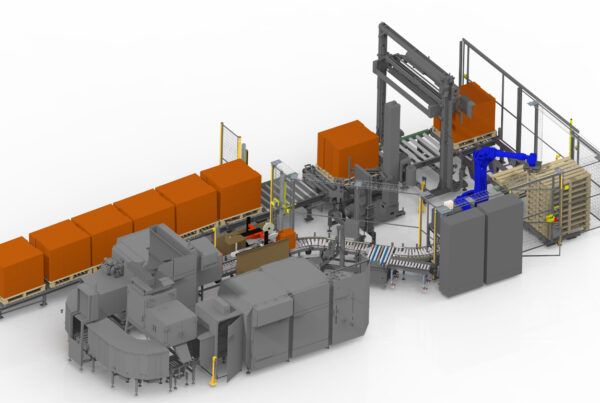

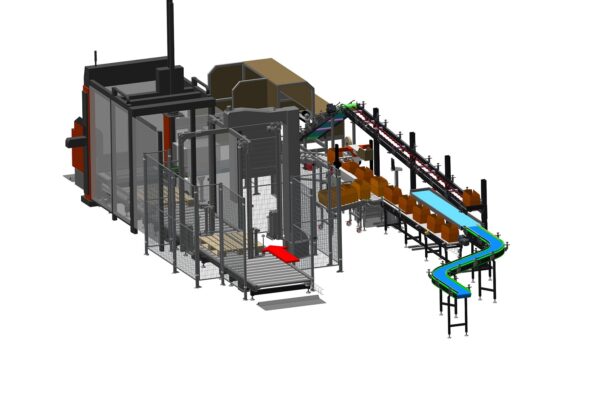

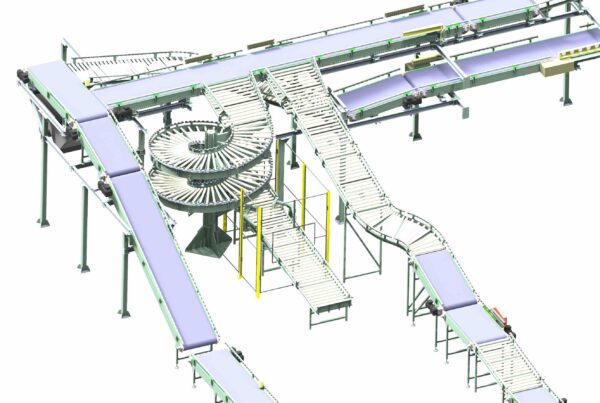

Packaging line for baked goods

'.get_the_title().'

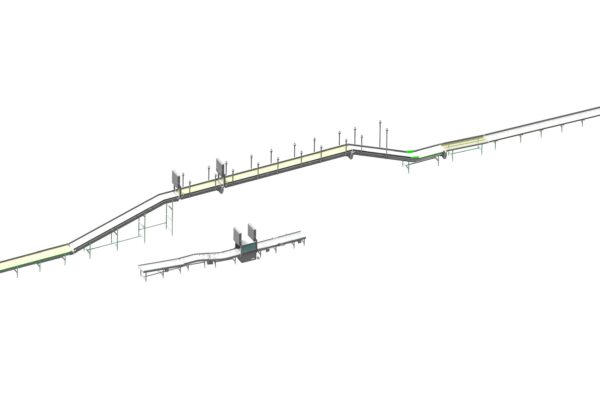

Automatic conveyor system for tyres

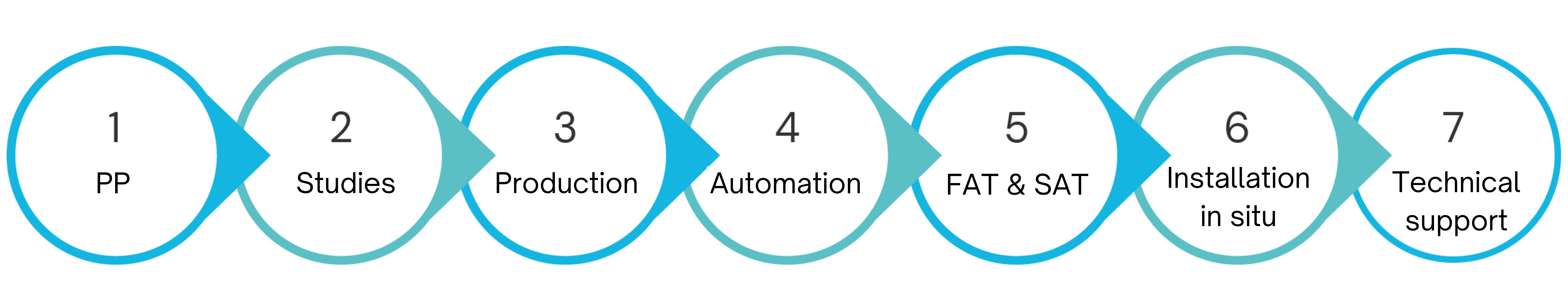

OUR PROJECT PROCESS

Chronology of your projects

Our pre-project team, consisting of an expert from each field – a sales engineer, a design engineer and a pre-sales technician – advises all our customers in their search for solutions. Depending on the customer’s needs, this team can provide advice in order to conceive and design the project they want with specific solutions.

: Our engineers and project designers model and conceptualise all the projects you want. Our teams visit your sites to adapt our conveyor lines to your environment. They model the project, which is then designed methodically by our design office.

Each team receives the plans and produces their parts of the conveyor.

Our automation technicians program the electrical system to suit the customer’s needs. They adapt to any additional machinery integrated into the line and take every detail into account to build the lines you need.

Our assembly staff put the complete lines and conveyors together. Everything is pre-tested in our workshops with quality controls at every stage.

Next, our assembly staff install the production lines at your premises and re-test their operation before commissioning.

If you have any technical questions, belt changes or modifications to make to any of our conveyors, our quality department can answer all your questions. They will put you in touch with the qualified staff who will be able to respond directly to your problem.